We improved on-time delivery of N American remanufacturing operations of an industrial OEM by optimizing Inventory

Key Business Challenges

- Industrial OEM with over 1,000 SKUs (FG) with persistent high levels of backorders while competitors offered similar products to customers at lower prices and short lead times

- Complex bill-of-materials and supply chain with over 14,000 components. Manual planning processes that did not have process clearly defined needed to be redefined

- Lack of clearly defined KPIs for suppliers, resulted in lack of clarity on root-cause analysis

Client Expectations

- Developed a forward looking model to determine component outage, enabling analyst to trigger expedite process from suppliers

- Developed tracking templates to be utilized by the client in the on-going process

Decreased backorder for pilot by ₹1.5-₹2 million

Analytics/Consulting Project

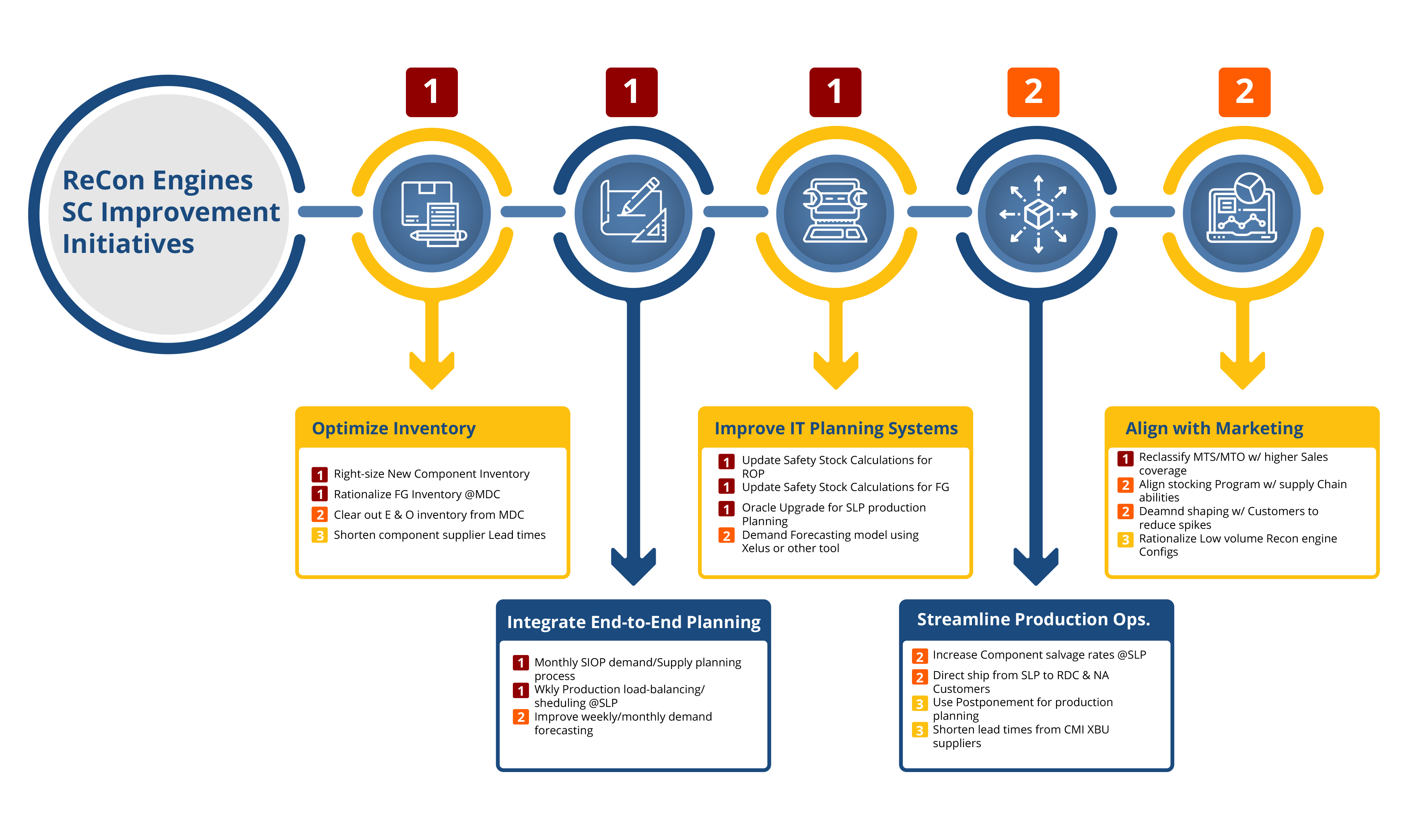

- Provided an end-to-end assessment of demand and supply chain planning process for the remanufacturing plant in Mexico

- Assessed process gaps in demand planning, inventory target setting production planning. across the entire remanufacturing supply chain

- Incorporated more accurate safety stock formula to account for multiple factors in the supply chain

- Developed a multi-echelon inventory deployment model that accounts for various service levels at multiple nodes

- Implemented recommendations on a smaller sub-set of products as a proof-of concept pilot

Incorporated a dynamic safety stock calculation for FG and RM

SUMPURA Delivered Outcomes

- Improved inventory stocking strategy to use differentiated service levels across separate item classifications. Implemented dynamic safety stock calculation for FG and RM using risks of supply & demand variability

- Implemented new FG made-to-stock vs. made-to-order classification requirements. Implemented weekly raw materials expediting procedure through future delivery and consumption simulation

- Improved communication between manufacturing and distribution sites by enforcing accountability. Refined supplier communication through procurement analytics

Identified other techniques to improve forecasting 7%-9%