Consolidated multiple aftermarket organizations into one global organization thus saving more than ₹100 MM annually

Key Business Challenges

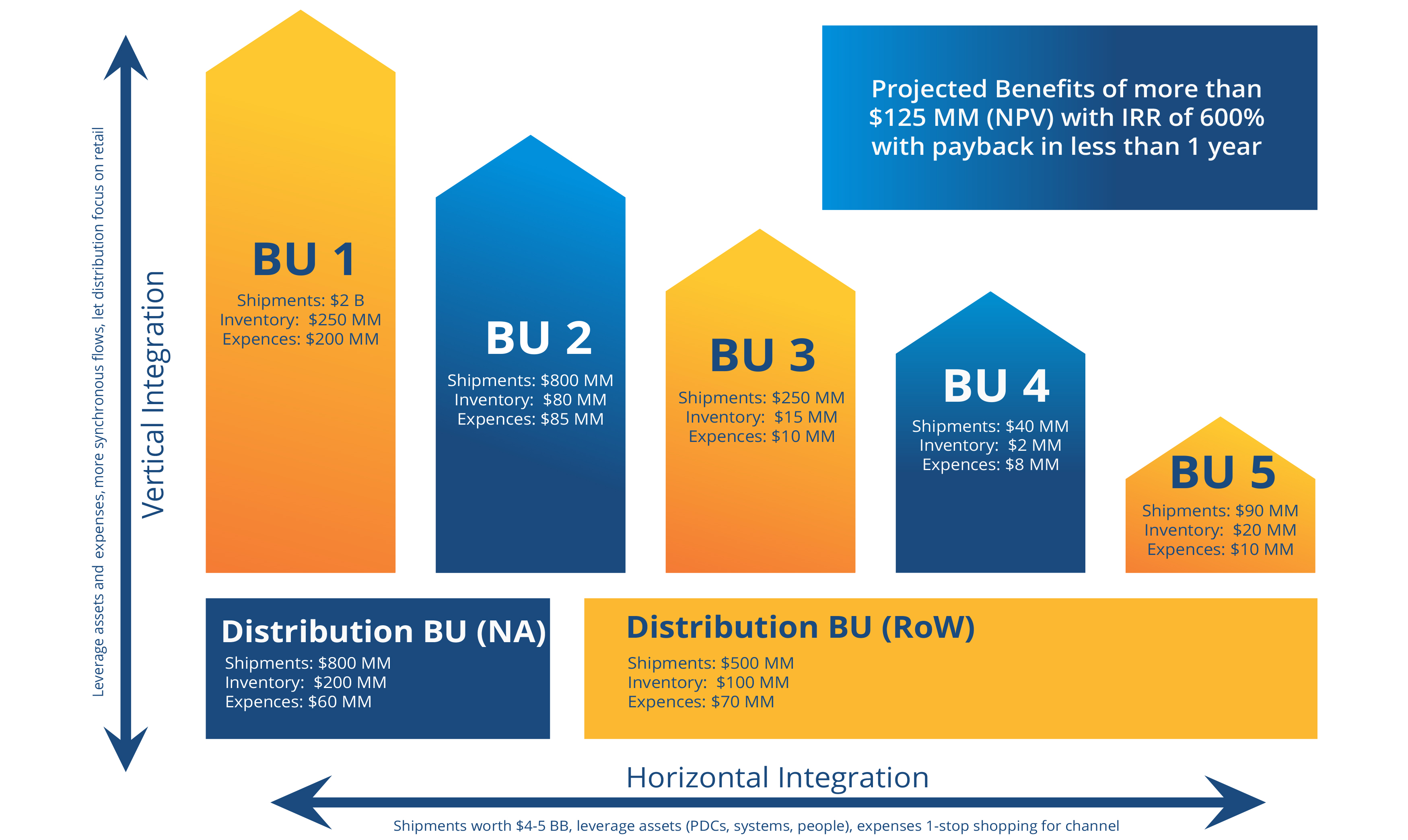

- Client had multiple Aftermarket distribution orgs in various business units (BU), which independently fed multiple retail channels resulting in lots of inefficiencies

- According to a previous customer study aftermarket service across all BUs was quite poor, esp. compared to competitors.

- Many facilities directly overlapped and over 80% of spend in running an PDC was for freight, payroll, rent

Client Expectations

- Developed business case for merging various groups into one, considering multiple scenarios

- Developed appropriate operating model for cost sharing between all the BUs, esp. since aftermarket segment is the most profitable for each BUs

Proposed an Integrated Aftermarket Distribution Business unit in the company

Analytics/Consulting Project

- Led a cross-BU working group to evaluate a phased integration of all the distribution orgs into one to provide: competitive cost structure, improve customer service levels and a better governance/business model

- Evaluated IT system compatibility, process similarity (incl. order management, warehouse, transport, inventory, master data management etc.)

- Assessed current leases/contracts of facilities, future space requirements

- Estimated hard benefits (NPV, Investment Capital) and soft benefits (improve service level, gain market share, cross selling oppty). Customer satisfaction with parts logistics could enhance ability to harvest more sales/PBIT by adding market share of Part sales, service, and service price premium

Evaluated synergies of combining 7 BU’s aftermarket groups around the globe into one

SUMPURA Delivered Outcomes

- We recommended creating an Integrated Aftermarket Distribution BU as a standalone cost center responsible for warehousing, packaging, kitting, materials planning, inventory control, parts distribution/Transportation…

- Proposed reducing total number of facilities from 61 to 25 over a Timeline of 4-5 years.

- Payroll reduced 15%, OpEx reduced 10%, Transportation Costs reduced 5%, Indirect Sourcing Cost reduced: 10%

Proposed combining 61 facilities into 25, saving ₹125 MM (< 1 yr. payback for the company)