Developed end-to-end supply chain costing to design an optimal network to support new product introduction in China

Key Business Challenges

- With continued uncertainty surrounding the adoption of new emission standards, the client did not want to invest capital given the uncertain market dynamics in China

- Client was unsure as to the level of service expected by its customers and the level of service offered by its competitors

- Client required a cost-to-serve model that is capable of processing multiple scenarios per customer

Client Expectations

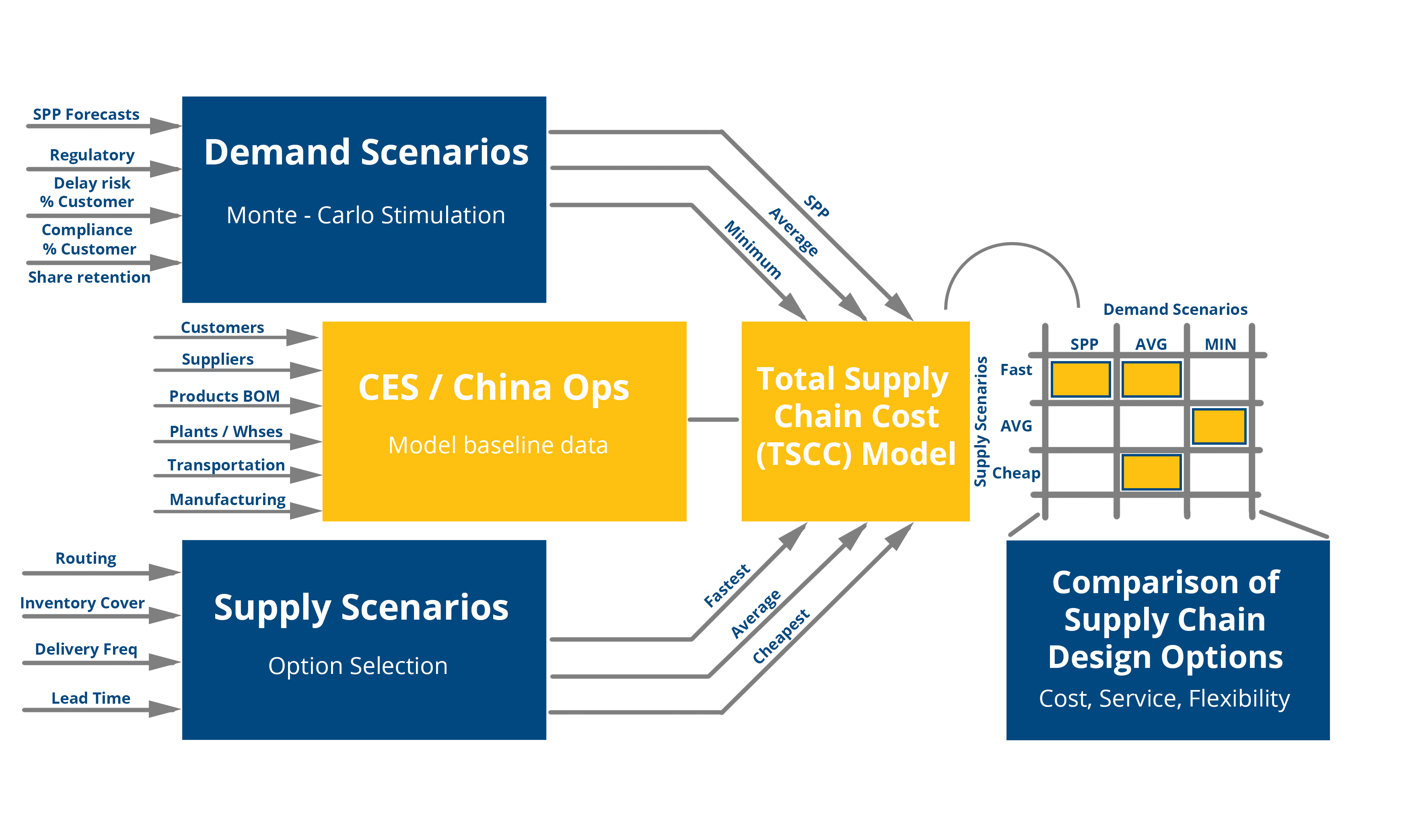

- Built a Monte Carlo Simulation Model to balance the risk/reward surrounding the market potential with that of the regulation uncertainty

- Improved working capital by increasing payment terms by 30%, increased supplier-owned inventory

Developed PAC strategy to for delayed product differentiation

Analytics/Consulting Project

- Conducted customer research for client to help them understand the China market and their customer expectations

- Developed customer segmentation and simulated various demand scenarios for sensitivity analysis

- Built detailed process definitions to evaluate current capabilities for end-to-end planning and identified process gaps

- Market research enabled the construction of a segmentation strategy for the client and provided a competitive market assessment on clients capabilities versus the competition

- Develop a financial model that take into account cost, flexibility, and responsiveness while managing risk of over and under investment

Monte-Carlo simulation of demand risks indicated likely loss of 30%-90%

SUMPURA Delivered Outcomes

- Developed a detailed cost to serve model, that is capable of conducting multiple scenario analysis

- Recommended the construction of an alternative manufacturing strategy to shorten lead-time to the customer that satisfies customer expectations

- Assessed current supply chain planning process and suggested improvements to S&OP process

- Developed an implementation plan to roll out supply chain with highest flexibility to minimize capital risks

Redesigned supply chain to reduce costs (~4% COGS to 2%)